The following is a message from AAW Board Member Dale Larson.

We know from AAW surveys that around 50 percent of our members have been to at least one national symposium. My hope is that we can persuade many of the other half to attend – beginning with our 25th anniversary gathering in Saint Paul, Minnesota, June 24-26.

We know from AAW surveys that around 50 percent of our members have been to at least one national symposium. My hope is that we can persuade many of the other half to attend – beginning with our 25th anniversary gathering in Saint Paul, Minnesota, June 24-26.

This will be a very special symposium. We have invited all living Honorary Lifetime Members, as well as all of the demonstrators who have participated in past symposiums. These include some of the biggest names in woodturning over the last quarter-century. Nick Cook, Dale Nish, Alan Lacer, Al Stirt, Ray Key, Dick Gerard, David Ellsworth, Albert LeCoff, Giles Gilson, and Jane and Arthur Mason, among many other notables, will be in attendance. A complete list of the outstanding demonstrators and panelists can be found on our web page.

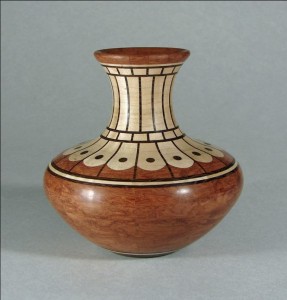

Attendees will see the largest collection of turned art in the world this year. The Instant Gallery will be amazing, and each attendee is invited to bring a turning for display or sale.

The trade show will be our biggest yet. Every major lathe manufacturer will have the latest models on hand for you to admire, try out, and salivate over. You will need to bring your checkbook and credit card to fix the problem with those missing items in your shop.

The demo agenda is ambitious and varied. There will be 16 rooms set up for demonstrations and panel discussions and the classes will go on for three full days. You probably won’t be able to take in all the classes you want, but key demonstrations will be captured on video.

The Professional Outreach Program has pulled together a great exhibition entitled ‘Roots – An Artists Vision’, there will be a retrospective exhibit of work by 2011 POP Merit Award Recipient David Ellsworth. POP has also set up the Emerging Artist program highlighting outstanding new turners during the lunch hours, and slated a full list of panel discussions covering all areas of woodturning. Three other exhibitions will be on site; ‘Turning 25 – A Celebration’, ‘Doing a Good Turn – A $25 Souvenir for the 25th’ and the Return to Community ‘Empty Bowls’ sale of donated turnings.

Bonnie Klein and Larry Miller have set up a terrific schedule for the Youth Room. Bring your kids and grandkids and sign them up for a class, or volunteer to help with the hands-on training on mini-lathes. Every kid who turns during the symposium will get his or her name put in a hat for the drawing that will give away the 25 Jet mini-lathes and related equipment. We’re sure to hook some of them as future AAW woodturners.

And to convince your spouse that this is a vacation for two, we have a full schedule of demonstrations and talks in the Spouse Craft Room. We also have tours set up for our members who want to see the Saint Paul area. Again, the schedule for all these classes and tours can be viewed on the website.

John Hill will convince you to part with your money at the Educational Opportunity Grant Auction after the banquet on Saturday night. The proceeds from the auction are turned around and given out to our members and chapters the following January as financial grants. The EOG program is one of the great benefits of AAW membership.

And, if you are an ornamental turner, segmented turner, or pen turner, you will have lots of options on Friday’s Special Interest Night to meet like-minded colleagues. We also will have topics on First Aid for Woodturners, Antique Lathes, 501(c)(3) status for your chapter, Gizmos and Gadgets, and Bowls. We will have tables set up for book signings, including the AAW’s 25th anniversary retrospective, Kevin Wallace’s book on the Lipton collection, and David and Ruth Waterbury’s new volume on their one-of-a-kind woodturning collection.

This will be the kickoff of a wonderful year for AAW. We hope you will arrange to be in Saint Paul for our best symposium yet – one that you don’t want to miss!

Dale Larson

American Association of Woodturners