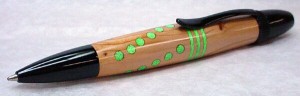

Inlays can be created by making a recess in the turning and filling with a contrasting material, such as metal powder or crushed stone. The photo inset is one such example of this type of inlay. This was created by Ed Davidson, a.k.a. YoYoSpin. He has a large number of video tutorials on his website, yoyospin.com, as well as offering DVD tutorials titled Yo-Yo Turnings, Closed End Pens and Creating “Outlays” from Inlays. His instructions cover many subjects including pens, pendants, bottle stoppers, rose engine and the Beall Pen Wizard.

Many pen turners have a mini-lathe and the 1” post on the Oneway Drill Wizard won’t fit. This got me to wondering if there is an alternative to this jig.

Many woodturners, and woodworkers in general, design and build their own jigs. This is also true for a lathe drill jig, although I had difficulty in finding tutorials for building one. The Sydney Woodturners in Australia have a page with pictures and basic description for building a Lathe Drilling Jig. But other than that, not much on building your own.

A quick internet search indicated the the Sorby Precision Boring System was not available in the U.S. A quick email to Robert Sorby in England confirmed this. However, Lindesy Reynolds from Robert Sorby recommended ordering from www.turners-retreat.co.uk

A drill jig can be used for many other operations, the most common of which is drilling turned chair legs.