The Segmented Woodturners virtual chapter of the AAW has released the January Club Summary. Here are some of the goings on:

Chapter Challenge

Chapter President Malcolm Tibbetts has announced the Winter 2012 Chapter Challenge which will focus on feature rings. Here are the rules:

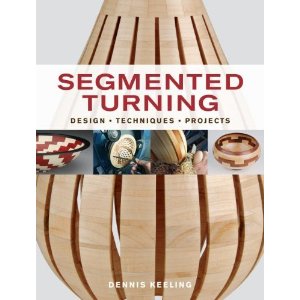

New Segmented Woodturning Book

SWT member and current officer, Dennis Keeling has written a new book on Segmented Woodturning. It will be available from Amazon here in the US on February 7th and can be pre-ordered now. For more info or to purchase, click this link: Segmented Turning – Design*Techniques*Projects (UK buyers can get it from GMC in March.)

SWT member and current officer, Dennis Keeling has written a new book on Segmented Woodturning. It will be available from Amazon here in the US on February 7th and can be pre-ordered now. For more info or to purchase, click this link: Segmented Turning – Design*Techniques*Projects (UK buyers can get it from GMC in March.)

The pre-order price from Amazon is $16.47 (plus shipping unless sale > $25) which is a savings of $8.48 off the cover price.

Dennis will be at our October Symposium and would be happy to sign your copy.

Forum Discussions

The education you get from the forum is more than worth the annual dues. Here are some recent topics:

- Segments on End Grain – This forum thread asked about techniques in adding collars to segmented vessels made from staves. There was a good discussion on the best ways to build this type of vessel.

- Table Saw Recommendations – This was an interesting thread with lots of inputs. Most people like their table saws and there are wide range in use including the new Stop Saw machines. Cast iron tables seem to help accuracy as well as good blades. I recommend reading this thread if you want to learn more about table saw choices by our members.

- Walnut Source Recommendation – Where do you get your walnut? Several excellent ideas were shared here.

- First Feature Ring – If you’ve had problems with the sandpaper on your Performax 16-‐32, then you should check out this thread.

- Tap and Die set for 1 1/4 x 8 – spindle In this thread, you can find some good recommendations for purchasing spindle sized tap and die sets for your lathe spindle.

Recent Photos

There are really masterful pieces being created by the members of this chapter. Here are a few:

Bowl made from alowood ebony, alowood walnut and I believe aspen. 80 segments per ring, less at the base. Total number of segments 2391. The bowl is 10.75″ wide, 4.75″ high. Segments were made with Byrnes table saw and a protractor accurate to .05 degrees. Method of construction per Bill Smith for open segmenting. The high accuracy of the segments allowed me to construct it this way.

Assembly: William Smiths jig for open segmented turnings. Used byrnes table saw and digital protractor. Went further. Made test pieces and made the angle exactly 2.25 degrees. After that, nobody so much as sneezes around that machine. Installed the first segment and waited 5 minutes. Then I pushed one segment against that one, forcing it against the steel platform of the jig. I used aspen, which has a low mod of elasticity. That helped. The last 10 pieces I put in at the same time pushing them in hard, causing high ring pressure because of the arching that way closing any gap that may still have been there.

Finish: 2 coats of Bullseye seal coat, 6 thin layers of wipe on poly. Alowood is manufactured wood, excellent to work with, however, economy forced them to stop production.

This bowl is 8 inches diameter at the top and five inches high. It is made from 1176 segments of maple, mahogany. padauk, wenge, amarello and purple heart. The base is floating and is veneered (both sides) MDF. I chose this type of base because a a separation of solid segments on a similar vessel I had made previously.

Upcoming woodturning classes:

May 20 – 26, 2012 Easy Segmented Platters and Expressive Wall Art

Instructor: Linda Sutter

John C. Campbell Folk School

June 3 – 9, 2012 Turning in the Polychromatic Style: Staved Construction

Instructor: Don Russell

John C. Campbell Folk School

June 25 – 29, 2012 Segmented Turning: pushing your skills to the next level

Instructor: Curt Theobald

Anderson Ranch

July 8 – 14, 2012 Segmented Turning

Instructor: Malcolm Tibbetts

Arrowmont

September 4 – 8, 2012 Segmented Turning: Where Precision Partners with Turned Elegance

Instructor: Malcolm Tibbetts

The Mark Adams School of Woodworking

Chapter web stats:

The chapter website received 5,281 unique visitors in October and 274,488 page views.